Barloworld revamps its rebuild centre and upskill artisans

Caption:

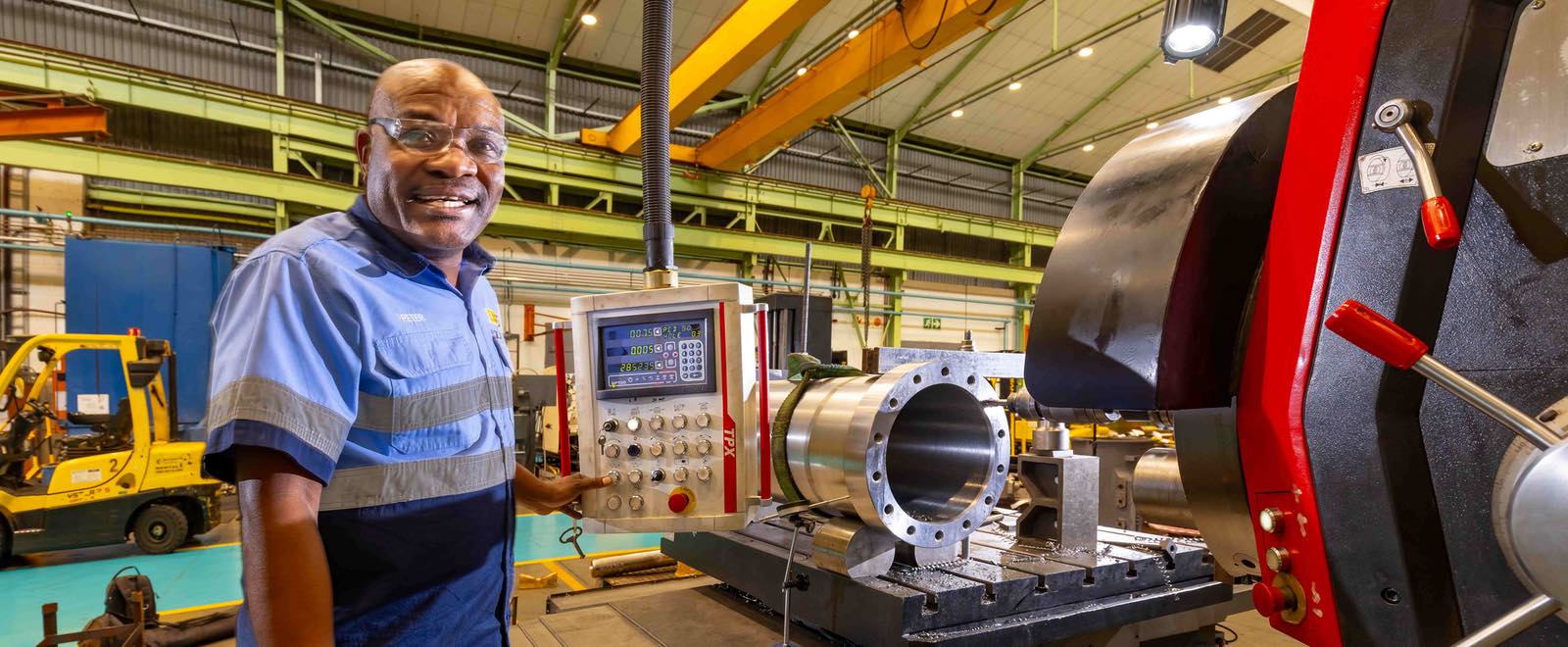

A technician is refurbishing a component at the Barloworld Rebuild Centre in Boksburg

📷 SUPPLIED

The Barloworld Rebuild Centre (BRC), where worn components of gigantic earth-moving machines are resurrected and given a second life, is an artisanal marvel.

The facility -- situated in Boksburg, 24 kilometres east of Johannesburg -- has recently undergone R68 million technology and operational upgrades, which have enhanced its component rebuild solutions, and expanded its machining and salvaging capabilities.

“The BRC’s new state-of-the-art equipment reduces component rebuild turnaround times. It also affords our customers to make a determination regarding whether to repair or replace damaged components, depending on cost implications and how worn the components are,” says Kamogelo Mmutlana, executive head of Business Excellence at Barloworld Equipment (BWE).

The 30,000-square-meter facility, which is the size of four football pitches, is the largest component rebuild facility within the BWE global dealer network.

Since BWE is Africa’s largest Caterpillar (CAT) dealer, the BRC has been built to CAT rebuild standards, offering specialised component restoration and salvaging services to seven countries in Southern Africa.

The BRC’s core business is to rebuild components, thereby reducing the need for customers to buy new units from CAT. Although BRC’s core business is to rebuild damaged CAT components, it also sells new CAT parts. In fact, it is the second biggest consumer of new CAT parts within BWE’s dealer network.

At any given time, there is about R1 billion worth of inventory in the facility. The BRC is always a hive of activity employing about 250 technicians and artisans, who rebuild and salvage about 2,000 components a year.

BWE customers bring components such as engines, diffs, axles, transmissions, cylinders, pumps, valves to the facility. All components are refurbished, tested, and painted before they are returned to customers for installing into earth-moving mining and construction vehicles like excavators, trucks, loaders, bulldozers, and graders.

According to Mmutlana, BWE is accelerating the training of new technicians through its three-year artisanal training programme and CAT’s training-to-task methodology, which blends foundational technical skills with modular assembly training.

“We’re combining elementary technical training with the training-to-task approach so we can tap into a bigger pool of prospective technicians and get them productive faster, without compromising quality,” explains Mmutlana.

Over the last 16 years, BWE has trained roughly 1,800 engineering learners, including apprentices and the old NQF Level 3 learners.

BWE recruits about 110 trainees per year, which are split into two cohorts. Prospective recruits are required to have matric and must be competent in maths and science, or must possess an N2 in engineering studies.

“The majority of the trainees are absorbed by BWE while a very limited number opt to explore opportunities outside of the company since they are usually poached as soon as they complete the programme. CAT-certified technicians are a hot property,” says Mmutlana.

According to BWE, approximately 25%-30% of the trainees that graduate from its training programme are recruited elsewhere while 65%–70% of graduates are absorbed by the company. The BRC absorbs between 4 to 8 qualified artisans annually from the programme.

CAT-certified technicians are highly sought after in the earth-moving and heavy equipment market, where BWE is facing a stiff competition for talent from other CAT dealers and its major competitors like Liebherr, Komatsu, and Bell Equipment -- which often poach artisans and technicians in the South African market.

In South Africa, earth-moving equipment mechanics, which are equivalents of CAT technicians, earn on average about R575,000 to 626,000 a year, which is about R48,000 to R52,000 per month, according to Glassdoor, an American job search engine. These pay scales depend on experience, certification level, role (field vs workshop technician), and employer.

Some online job listings for diesel mechanics for excavators and drill rigs list their potential salaries in the range of between R27,000 and R35,000 per month.

In more prosperous regions like North America, Europe, and Australia, earth-moving technicians and artisans are paid a lot more than in South Africa.

Glassdoor shows that service technicians can earn anything between $55,000 and $78,000 annually while technical training specialist, who train CAT technicians, command salaries ranging between $95,000 and $140 000 a year, depending on experience.